TPS digital cutting machine in automotive interior industry mainly cuts soft material like foot pad, car cushion, leather seat cover, trunk mat, shading pad, steering wheel cover etc. with fast speed, strong stability, high accuracy and good quality. Whether mono-layer cutting or multi-layercutting, it will help customers produce perfect products within limited time and area,it provides the best solution of intelligent cutting program in automotive interior industry.

Equipment features:

1.TPS Technology researched and developed CAM software independently which prevents over-cutting at inner angles to recover graphic outline maximally.

2.Intelligent tabletop mapping function: the flatness of tabletop is measured with tabletop mapping by the high-precision height detector, and the tabletop can be height-compensated in real time by the TPS software to ensure perfect cutting result.

3.Realize matching the cut shapes of front and back sides intelligently according to the material edges.

4.Automatic tool calibration: Quick and effortless tool exchange thanks to the fiber laser tool-tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

5.Quick-replacement universal modules make simple and efficienct operation and save tool-changing time.

6. Automatic feeding device apply for roll material cutting.

7. Multi-task repeat cutting, intelligent absorption.

Cutting material

TPS digital cutting machine is equipped with advanced tool module quick replacement, which is strongly universal, easy, convenient and handy.

-

Universal tool module

-

Universal tool module and tool unit

-

High performance high speed Milling Router

-

Multi-angle V-Cut tool

-

Creasing tool

-

Wheel-cut tool

-

Electric Oscillating knife

-

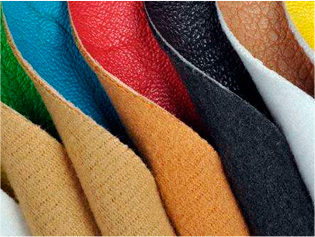

Leather

Foot pad, automative cushion,

Tool selection

trunk mat, leather seat cover,

steering wheel coverOscillating knife

-

PVC

Tool selection

Foot pad, trunk mat

Drag tool

-

Fabric

Tool selection

Seat cover

Wheel-cut tool

-

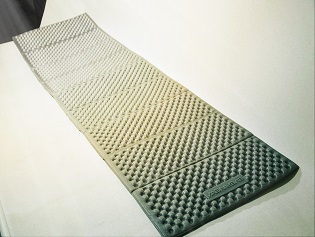

Plastic loop

Tool selection

Foot pad, trunk mat

Oscillating knife

-

Plush material

Foot mat, trunk mat

Tool selectionOscillating knife

-

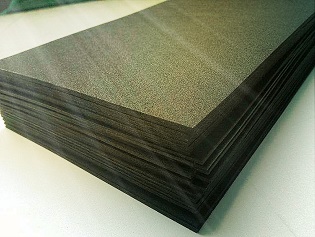

EVA

Trunk mat

Tool selectionOscillating knife

-

XPE

Trunk mat

Tool selectionOscillating knife

-

Blended material

Seat cover, foot mat

Tool selectionDrag tool

Hardware advantages of cutting machine

Quick replacement tool modules

TPS digital cutting machine is with advanced, standard and universal tool modules for replacing tools easily and quickly. It is very handy during processing a wide variety of materials.

Multiple tools

Full range of tools: router, electric oscillating knife, V-cut tool, drag tool, creasing tool, kiss-cut tool, plotting pen etc. Different tools for different materials.

Magnalium Vacuum Absorption Tabletop

The tabletop is durable and non-deforming with vacuum absorption design: strong wind strong suction.(easy for absorbing small items)

Vacuum cleaning pipe and base stand

The whole cutting process is without smell and dust, which is good for workers’ health and up to the environmental protection standard.

European design style

Under the idea of European industrial equipment design, the machine is top-end, stylish and technological on the premise of ensuring machine performance.

Welding integrated base stand

The welded frame is more stable, more rigid and warp-proof.

Quick tool replacement module

Universal module can be combined with tools freely, realizing quick replacement of tools.

Full range of tools

Router, electronic oscillating knife, V-cut tool, drag tool, creasing tool, kiss-cut tool, wheel-cut tool(different tool for different material)

Honeycomb aluminum tabletop

It is durable and undeformable with vacuum absorption that has strong wind and strong suction.(easy for sucking small items)

Tabletop belt

It is made by imported material, durable, has good air permeability and a long service life, which reduces costs to minimum.

Sealed dust-proof design

Sealed dust-proof design reduces the failure rate of machine and extends its operating time.

Emergency stop buttons at 4 corners

If there is an error operation, press the button to stop the machine to reduce loss.

Interference immunity

Because of the complex electromagnetic environment, machine is especially equipped with anti-interference operating screen in case of blurred screen.

Safe operating environment

Infrared automatic induction safety device will maximally ensure operators’ safety while working and at the same time avoid material waste.

Rolling media feeder

The guide roller feeding device ensures that the feeding process in cutting is smooth and fluent. It can be set according to roll material’s specifications and features to enhance both output and cutting quality.

Software features

TPS digital cutting machine adopts self-researched and self-developed CAM software, in which users’ needs are perfectly considered. It is a full-automatic intelligent cutting system that integrates performance, speed and quality, which can realize various craftworks like full cutting, half cutting, boring and milling, punching, creasing, marking etc. Easy operation, multiple and practical functions, together with tool modules quick replacement can meet customized needs of users.

Automatic tool calibration

Tool or bit exchange is fast and effortless thanks to the fiber laser tool tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

High definition CCD camera

The high definition CCD camera can realize automatic positioning and cutting on various materials, which eradicates problems like inaccurate manual positioning and print deformation.

Automatic switch of two heads

The cutting process realizes automatic switch of two heads and satisfies different craftwork needs of different materials.

Vacuum absorption

With strong wind and strong suction, the size of vacuum absorption area is selectable, greatly reducing electricity consumption.

Material automatic recognition

Material thickness can be automatically measured instead of manual measurement, then it will be recorded into the software.

Operating interface

The high-accuracy distance detector will detect tabletop evenness and real-timely correct it through software to realize accurate cutting.

Control system

High performance multi-axial motion control system is adopted, which is convenient and economical to maintain and provides personalized development service.

Working pattern

The servo motor drives screw and can connect with computer to preset and store knife depth and knife pressure.

Image design software integration

It is compatible with software like ArtiOSCAD, AutoCAD, Coreldraw, simplifying workflow of designers.

Overcut optimization

The self-researched and self-developed CAM software will optimize the overcut phenomenon, maximally restore graphic contour and realize perfect cutting effect.

Automatic tool calibration

Tool or bit exchange is fast and effortless thanks to the fiber laser tool tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

Graphic positioning

High definition CCD camera and edge automatic recognition can realize automatic positioning on various materials and match the front side with back side, eradicating inaccurate manual positioning, print deformation etc. Together with automatic transmitting function, it allows efficient and accurate cutting on large format graphic, enhancing both output and cutting quality.

Matching cut at front and back

This function, together with edge recognition, will swiftly recognize material edges, position and realize the graphic cut at front matching the back side one.

Data interface

The internet interface allows updating and maintenance remotely with fast transmitting speed and long distance. It can transmit with multiple computers simultaneously.

Material thickness automatic recognition

Material thickness will be automatically detected without manual measurement, then it will be recorded into the software.

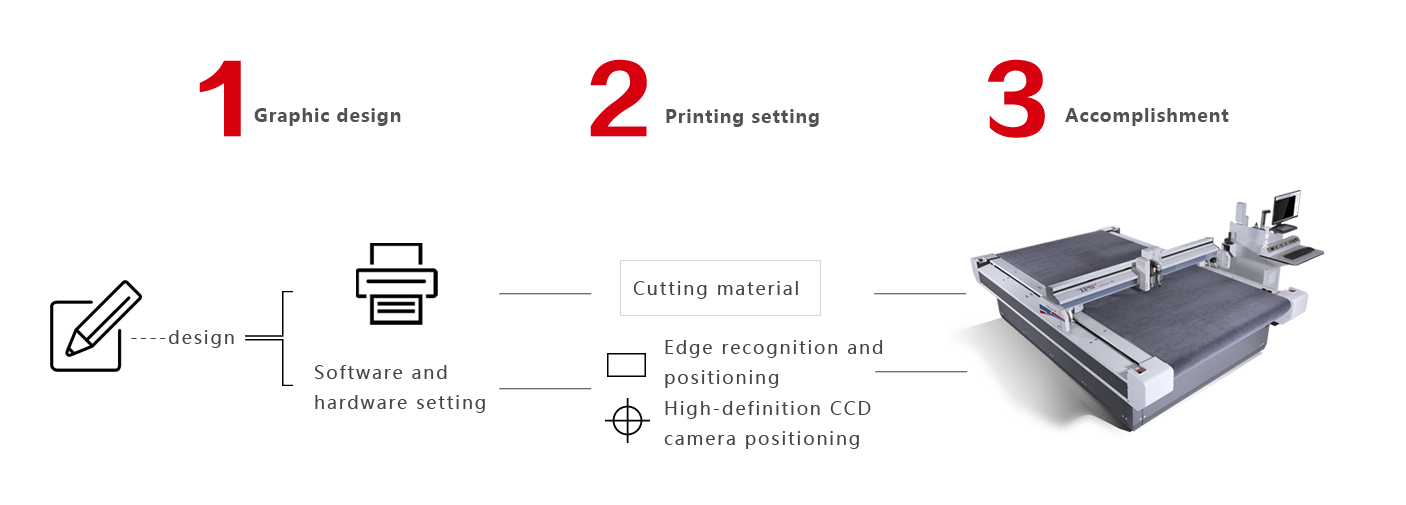

Cutting workflow diagram

Technical parameters

Main technical parameters of the machine

| Item: | Parameter: |

|---|---|

| Equipment power: | 2.5kw |

| Vacuum pump power: | 7.5kw |

| Voltage: | 380V 3 phase |

| Work area: | 1600x2500mm |

| Max. material size: | 1700x3000mm |

| Material max. processing height: | 50mm |

| Beam height: | 60mm |

| Max. processing speed: | 72m/min. |

| Servo motor qty: | 6pcs |

| Fixing method: | Welded integration |

| Cutting accuracy: | ±0.1mm |

| Positioning method: | High-definition CCD camera、Automatic edge recognition |

| Automatic media-feeding: | Yes |

| Applied material: | KT board, PVC foam board, PP, sticker, acrylic, corrugated board, honeycomb board, corrugated plastic, grey board, paper, leather, blanket, MDF, aluminum composite sheet, insulating board, fiber cloth, medium fiber board, flag fabric, textile fabric,etc. |